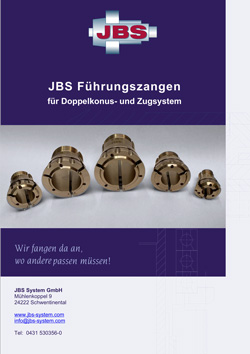

Collets

For over four decades, we have been developing customized, efficient solutions for the metalworking sector. Two of them are our JBS double cone and pull collets.

Our Double Cone And Pull Collets

The original directly from the manufacturer

The selection of the appropriate collet depends on the material to be processed and its diameter. Our collets are suitable for all kinds of materials, such as plastics, high-alloy chrome steels and steel according to DIN 1013, whether grinded or rolled. They run synchronously with the jackscrew and adapt to the material during machining. Changing the collets is fast and takes only 2-3 minutes, eliminating the need for complicated adjustment.

More than 6,000 collet models on demand

You need a flexible collet – we deliver! In our large warehouse in the north of Germany, more than 6000 different collet models are waiting for your order. And if it has to go really fast, we offer overnight and express shipping.

Contact us and we will be happy to advise you!

Our perfectionist

The Pull Collet

Our pull collet is suitable for all JBS Guide Bushing Systems. It consists of 3 segments held by springs and O-rings. Due to the higher concentricity and rigidity during milling, a better surface quality of the components is achieved. The lower contamination of the collet compared to the double-cone system ensures longer service life and lower maintenance work.

Our All Rounder

The Double-Cone Collet

The double cone collet is perfect for processing high quality materials with high tolerances. It can be used as a clamping and guiding collet and consists of 3 segments. The flexible collet is held by springs and gripping rings and the adjustment range is ± 0.4 mm. Buy the original at the best price from the manufacturer, that’s us!

Do you want some more?

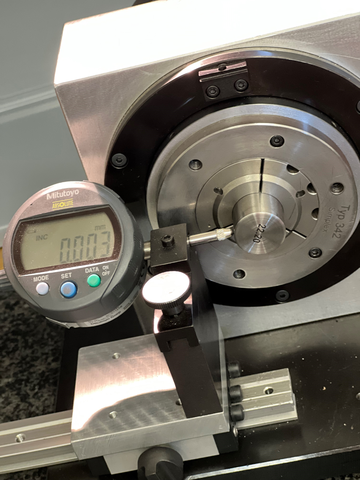

Increased concentricity for your collets

TRA – this means true running accuracy and describes our high-precision collets, based on DIN 6499. We offer all collets in the variants standard and TRA, so you always have the right product for your next order. A JBS collet has a maximum runout of 0.02mm. If you want it to be even more precise, we offer the TRA variant with a max. runout of less than 0.01mm.

All TRA collets are available as pull or double cone variant.

The JBS Special Collets

We produce individually according to your wishes

All models of our collets are available in double cone or pull versions.

Our special design of the JBS collet for hexagonal materials.

The angular slotted version of our JBS collet, which provides higher concentricity and more stable clamping force.

Our collet for flat materials

Our JBS collet for 4-edge material.

The JBS collet in the 'Extended Nose' variant, which offers better workpiece support through extended material guidance.

We also manufacture our collets for individual shapes. Please contact us for more information!

Which material do you process?

We have the right collet for every material. If you are processing a special material, we will be happy to advise you and offer you a custom-fit solution.

Depending on the material you are processing, we recommend different types of collets. You can find a material recommendation here

We also have intermediate size collets for the same price as the standard collets

We produce collets from AMPCO or grey cast iron. The grey cast iron can also be nitrided on request (ASP on request).

We have the right answer

Frequently asked questions - FAQ

We have compiled the most frequently asked questions to our customer service here. If your question is not listed here, please use our contact form and we will get back to you as soon as possible.

Orders

Our article key for pull collets

Here are the first three digits that represent the desired diameter:

317/36×40

322/26x35

342/53×50

346/32×40

378/44×40

485/59×60

601/28×40

Here you place the number

for the desired material of your collet:

1 = CLASSIC-nitrated

2 =CLASSIC-ASP coated

4 = CLASSIC-Ampco

5 = CLASSIC grey cast iron

This position indicates the number

for the shape you want your collets to have:

1=round

2 = 4-edge

3 = hexagonal

5 = diagonally slotted

7= special length

8 = extended nose

9 = profile / special collet

317/36×40

322/26x35

342/53×50

346/32×40

378/44×40

485/59×60

601/28×40

Here are the first three digits that represent the desired diameter:

317/36×40

322/26x35

342/53×50

346/32×40

378/44×40

485/59×60

601/28×40

Here you place the number

for the desired material of your collet:

1 = CLASSIC-nitrated

2 =CLASSIC-ASP coated

4 = CLASSIC-Ampco

5 = CLASSIC grey cast iron

This position indicates the number

for the shape you want your collets to have:

1=round

2 = 4-edge

3 = hexagonal

5 = diagonally slotted

7= special length

317/36×40

322/26x35

342/53×50

346/32×40

378/44×40

485/59×60

601/28×40

Example:

A round Ampco collet with an with an outer diameter 53×50 and inner diameter 12,5 is type 342 material 4 shape 1 inner diameter 125 = order no.: 342 4 1 125